8seg Technical Overview

Prologue

German hacker culture has this intense love for things that light up in colorful ways. Like for many others in this

community, I have always been fascinated by LEDs. One of the first things on my pile of unfinished projects was to build

my own LED matrix and use it to display text. When I started that project, I was still new to electronics. Back then,

commercial LED matrices were limited to red or green color only, and were very expensive, so there was an incentive to

build your own. At the same time, while individual LEDs were'nt expensive anymore, they hadn't started to be cheap yet,

either. On top of the material cost, back then there were no PCB fabs, and especially no PCB assembly houses that a

hobbyist could afford. Ultimately, I ended up never finishing this project because I felt it was more of a feat of

material wealth than of technical prowess.

Over time, LEDs came down in price, and peoople started using them in all sorts of fun things. Around the mid-2010s,

cheap-ish, ready-made tapes and chains of RGB LEDs that included WS2811 or similar digitally controllable driver chips

led to a cambrian explosion in projects involving large amounds of colorful LEDs since suddenly, all you needed was an

arduino and a beefy power supply to individually control an almost unlimited number of these LEDs.

Today, LED technology has advanced even furhter, to a point where now you can buy staggering quantities of the second

generation of these controllable LEDs that provides better color rendering embedded in all sorts of shapes, from tapes

through rings to grids. When I built the first matelight in 2013, the matelight's 640 individually-controllable LEDs

were a lot. Today, you can buy a roll with several thousand channels for about the price of a nice pizza.

The idea behind 8seg

Living through this amazing escalation of LED technology, in 2018, I looked at a then-obsolete piece of single-color,

dumb, non-controllable LED tape with a simple question in mind: Taking this unsophisticated artifact of yesterday's

technology, what would be the coolest thing I could build from it? Can I buld something that not only rivals, but

outmatches the modern controllable LED stuff? From that question, I set myself two goals. First, I wanted to keep the

project's use of financial and labor resources reasonable. A lot of art consists of taking a simple idea, and simply

extrapolating its implementation to a ridiculous scale at the expense of the artist's time and wallet. That wasn't the

point I wanted to make. I wanted to make something cool from an obsolete technology, not prove how much patience I had

soldering. My second goal was to create something that is meaningfully controllable. Controllability is much harder with

these dumb LED tapes, but it is possible nontheless, and I wanted to test out how far you could go with it.

After thinking through a number of possibilities, I settled on the basics of the 8seg design I ended up realizing. The

installation would be a banner-style display consisting of a series of characters made from non-controllable LED tape.

The banner can be rigged up in any convenient air space, bending and folding to conform to the space's shape and size.

The key idea behind 8seg is that it makes up for it's lack of control fidelity with sheer size. If nothing else, this

non-controllable LED tape is cheap.

The design of a single 8seg character

Each 8seg character consists of 8 segments of LED tape that are inter-connected through small circuit boards, four in

the corners, and one in the center. As it turns out, 8 segments arranged in this shape are enough to display all of the

English language's alphabet as well as numbers in a weird, but readable form.

The electrical design of an 8seg character has one weird trick at its core. To avoid having to run a bunch of wires from

some kind of driver circuit board to each of the eight segments, I thought, why not use the LED tape itself instead for

power and data transmission? Wires are heavy, expensive, and annoying to solder, so if I could find a way to

interconnect the LED tape so that it can all be driven from a driver circuit located at one of the character's

junctions while simultaneously powering that driver circuit, an 8seg character wouldn't need any wires at all anymore.

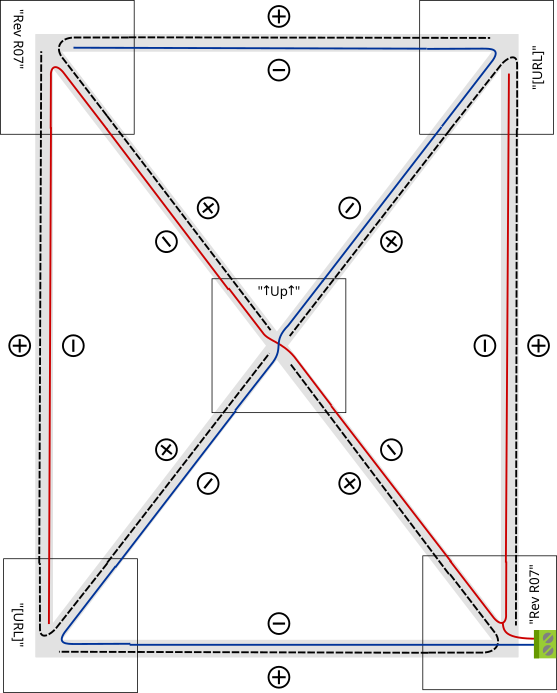

8seg achieves this feat using a circuit as shown in the diagram below. Interconnections between the LED tape segments

are done with a small circuit board in each of the four corners. The design is rotationally symmetric, and all four of

these boards are identicaly. The top right and bottom left corners simply use the back side of the same circuit board

used in the top left and bottom right corners.

The driver circuit sits at the center of the character and directly connects to the four diagonal segments. The key

thought behind 8seg's driving scheme is that there are two common phases wound through the display in a zig-zag pattern

as shown in red and blue in the schema below. These phases alternate their polarity at a high frequency. Each segment

has its negative pole connected to one of these two phases, and can be turned on by the driver while that phase is low

and the other phase is high. While a phase is high, the LEDs on all segments connected to that phase are reverse-biased,

and thus these segments remain dark.

The positive poles of all segments are connected to the driver circuit in the center through a spiral pattern. Each arm

of the spiral is made up of two segments, one diagonal on the inside, and one horizontal or vertical on the outside.

The two segments on each spiral arm are on different phases, one on each of the two phases. Thus, during a single cycle

of the two phases alternating polarity, first one of the two segments has its polarity the right way around, then the

other. The driver can turn on the active segment by connecting the spiral control line to the positive LED supply

voltage.

Both phases cross at the center where the driver circuit is located, so the driver can power itself from the two phases

using a simple full bridge rectifier.

Saving copper with point of load regulation

In the beginning, I experimented with the design above, putting 12V AC on the two phases, and letting the driver switch

its derived LED supply using some cheap MOSFETs. This simple design totally works, but it has an important shortcoming.

8seg is designed to be physically very large. This means that not only does it have a large number of LEDs that

together need a lot of current, it also has to transmit all of that current across significant physical distances. The

consequence of this was that in the initial design, I was looking at either needing hundreds of Euros worth of copper

cables, or burning hundreds of Watts of electricity into heat if I were to use thinner cables. In this case, cables act

like resistors. In a resistor, power dissipation rises with the square of the current inside the cable. This is bad for

8seg since it means halving the amount of copper in those wires increases power dissipation in these wires fourfold.

Despite that downside, this square law does come with an upside, too. If we assume we have wires of a particular fixed

diameter, if we can halve the current through those wires, we can quarter the wires' power dissipation. If we want to

deliver the same amount of power to the LEDs as before, to halve wire current, we have to double the voltage, and add

some circuitry on the drivers to convert that increased voltage back down to close to our LED tape's nominal 12V.

Alas, simply doubling the voltage leads to one question: How is it that we can pass double the voltage through our LED

tape to the center control circuit? Isn't the LED tape made for 12V operation only, not 24V? The answer to this

apparent problem is that the center is connected to the AC bus voltage only through the negative side of the LED tapes,

and controls their positive sides to turn them on or off. The AC bus voltage never appears directly across any single of

the eight segments. At the same time, a simple buck converter stepping down our new 24V bus voltage to 12V, and feeding

the segment control transistors with that instead of feeding them straight from the rectified AC bus allows us to feed

the segments with 12V. The only difference between this circuit and the straight 12V variant is that now, during OFF

times, the LED tapes see a negative 24 v across them. To make sure that's not a problem, I tested a number of them with

different LED colors and from different manufacturers, and all of them held up past the 50 V I could easily generate

with my lab power supply.

Synchronous rectification

I implemented the point-of-load regulation in a new revision of the center circuit, and built a prototype digit. When I

tested this prototype, to my dismay, I noticed some really strange behavior. In my tests, the LED tape did not properly

light up, and when I checked the voltages with my oscilloscope, I noticed that the center circuit's ground was floating

several volts below the AC bus voltage's negative phase. How come?

After some head-scratching, I found that this problem was due to a simple instance of Kirchhoff's current law. Consider

the point where the AC bus voltage's currently negative phase enters the center circuit board. Let's say that we

dissipate 24 Watts in the segments' LEDs. In this case, at 24 Volts, 1 Ampère will flow into the center circuit's

terminal connected to the currently positive phase, and out from the center circuit's terminal connected to the

currently negative phase.

Now consider the current through the LED tape. During one half-cycle of the AC bus, the center circuit can only address

the four segments that have their negative rail connected to the currently negative phase of the AC bus. If one of these

four segments is currently on and dissipating our 24 Watts, that segment will be fed 2 Ampère of current from the center

circuit through its positive rail. My mistake was that I did not consider what happened to the return current here.

The corresponding 2 Ampère return current of course flows back through the segment's negative rail into the center

circuit, and herein lies the issue: That negative rail is where our center circuit's supply current comes from! This

means that according to Kirchhoff's current law, the 1 A flowing out from the center circuit at its input are adding up

with the 2 A flowing into it. The result of this is that in the currently positive phase's connection, we get 1 A

flowing into the center circuit, while in the negative phase connection, we get (-1) + (+2) resulting in another 1 A

flowing into it! The only terminal where current flows out of the center circuit is the positive terminal connected to

the active segment, out of which 2 A of current are flowing.

The big problem with this confusing scenario is that this means the bridge recitifier in our center circuit cannot work,

since its negative-side diodes are reverse biased while any of the segments are on. We can't just add more diodes here,

since that would just short both AC bus rails together. Instead, the solution is to add one rather chonky MOSFET in

parallel with each of the two negative-side diodes of the bridge rectifier that are controlled by the center circuit to

act as a sort of synchronous rectifier. When we turn on one of the segments, we have to turn on the MOSFET on the

currently negative rail to allow the segment's return current to bypass the bridge rectifier's negative-side diode. Fun

fact: If we turn on the wrong MOSFET out of the pair, we short the AC bus, resulting in a very quick end of life for that

poor MOSFET.

Power line data communication

As we saw above, the driver providing power to a string of digits has to continuously alternate the polarity of its

output voltage to provide one part of the digit circuits' multiplexing. Since we want to provide the control information

to the center circuits through those same two wires, we can choose between a number of viable power line communication

schemes. These schemes usually require a beefy transmitter adding a modulation at a frequency much larger than the

underlying bus frequency, and a filter circuit at each receiver to filter that signal from the much stronger fundamental

AC waveform. In our application, I saw two issues with these classical approaches. First, they require fairly complex

circuitry, especially the beefy transmitter at the driver. Second, they are susceptible to attenuation with either

changing load or over long distances, which could potentially be a problem with the high currents and long(ish) wiring

runs 8seg needs.

Because of these disadvantages, I decided on another approach entirely. Instead of modulating our control signal on top

of the AC power waveform, we modulate our control data into the AC power waveform. To not interfere with the display

and cause outages or flicker, and to avoid having to blank the display during transmissions, we choose a modulating

technique that leaves the proportions of negative and positive half-waves undisturbed. The practical realization of this

is that instead of alternating positive and negative half-waves, we send a positive half wave for each "one" bit, and a

negative half wave for each "zero" bit, effectively creating a phase shift keyed signal with two states with an

180-degree phase shift, with the transmitted bit rate synchronized to twice the underlying carrier frequency.

The remaining question is how one can encode arbitrary binary data into a continuous stream of ones and zeros that is

precisely 50 % ones and 50 % zeros across any time span longer than a few dozen bits. There exists a near-optimal

solution to this question from ethernet over copper twisted pairs. In ethernet, the encoded and modulated signal passes

through an isolation transformer to protect the ethernet transceiver from interference or dangerous voltages coming in

through the ethernet port. For this isolation transformer to work, the modulated ethernet signal must be exactly

balanced to avoid saturating the transformer's core with a DC offset. Ethernet solves this issue by using an encoding

known as 8b/10b encoding. 8b/10b encoding is named like that because it specifies a way to produce a 10 bit codeword

from any 8 bit input data word while guaranteeing that the resulting codewords are always precisely balanced when

looking at two or more consecutively.

Framing

Since 8b/10b encoding maps a space of 256 data words to 1024 code words, there necessarily are a number of unused code

words. While for some of them, leaving them unallocated is beneficial because it improves error tolerance by decreasing

the probability of one code word turning into another undetectably when a single one of its bits is flipped, even

accounting for that it leaves some room for other uses. In 8b/10b, these leftover code words are used for synchronizing

the receiver to the transmitter, and for framing transmissions. Synchronization is necessary for the receiver to know

where a code word stards, and 8b/10b has a handful of special "comma" code words that can be uniquely identified in a

continuous stream of received ones and zeros, because no other combination of 8b/10b code words could produce the same

sequence of ones and zeros of the comma code word anywhere.

The leftover code words that are not commas are useful, too. They can be used, for instance, as filler code words

betwene actual data transmissions, or to act as framing markers denoting things like the end of a protocol message.

The 8seg driver produces its modulation waveform by translating all data to be transmitted into 8b/10b codes, padding

the result with framing markers and filler codes, and copy-pasting together the corresponding AC waveform from a small

set of pre-programmed waveform transitions.